Contact Us

Surface Treatment

We support customizing surface coatings and surface colors based on your drawings or specific performance requirements.

MOQ: 500KG

Contact

E-mail: peter@wx-hfkj.com

Classification

| 🛠 Available Customization Options |

✔Coating Types:

|

✔Coating Properties:

|

|

🛠 Available Customization Options |

✔Color Options:

Custom colors available on request |

|

✔Standard Execution:

|

|

✔Application Matching:

|

Keywords:

Related Products

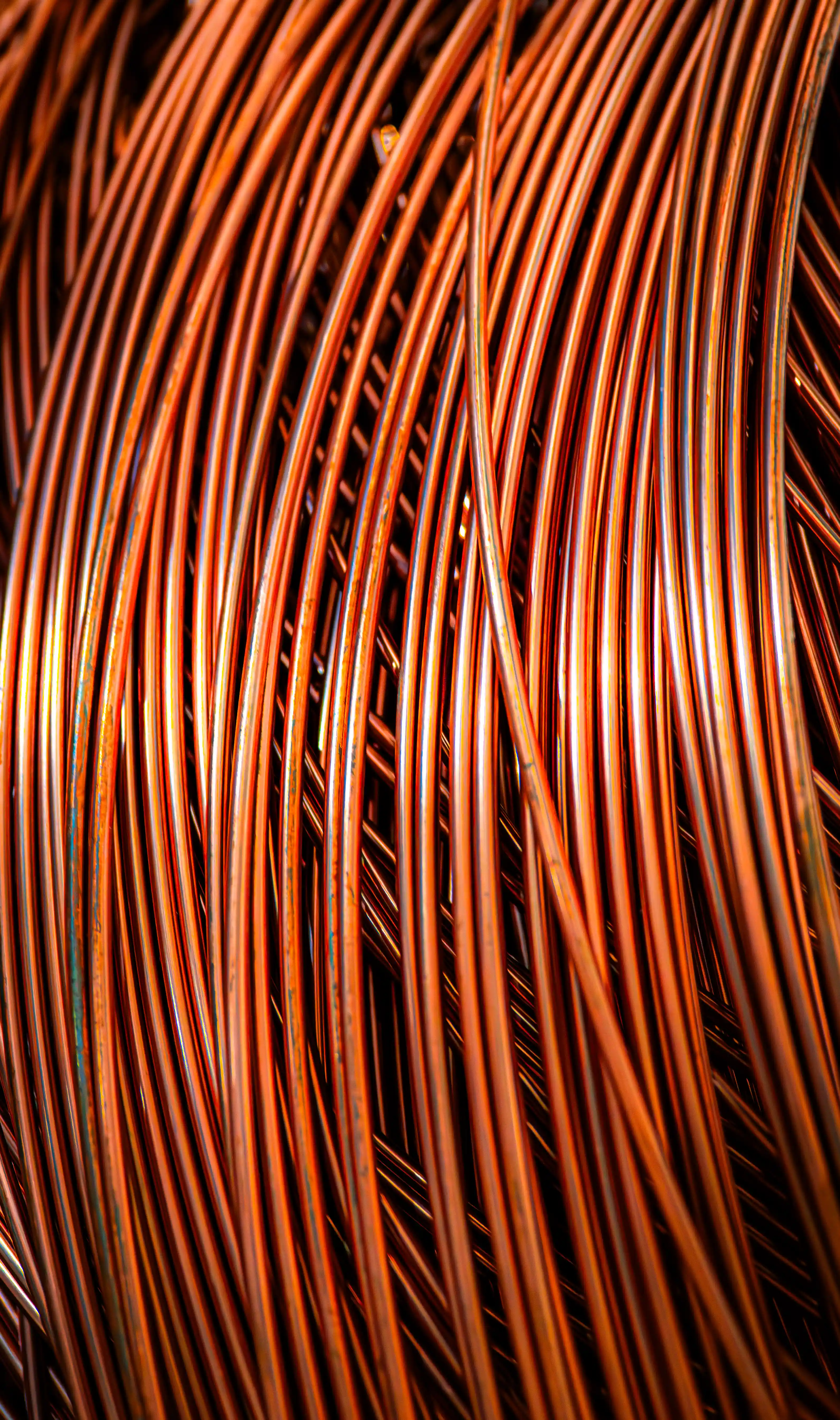

Spring Wire / Piano Wire(Uncoated)

SWRH62A / SWRH72A/72B / SWRH82A/82B / SWPA / SWPB / SWRS82A/82B (high-grade carbon steel)

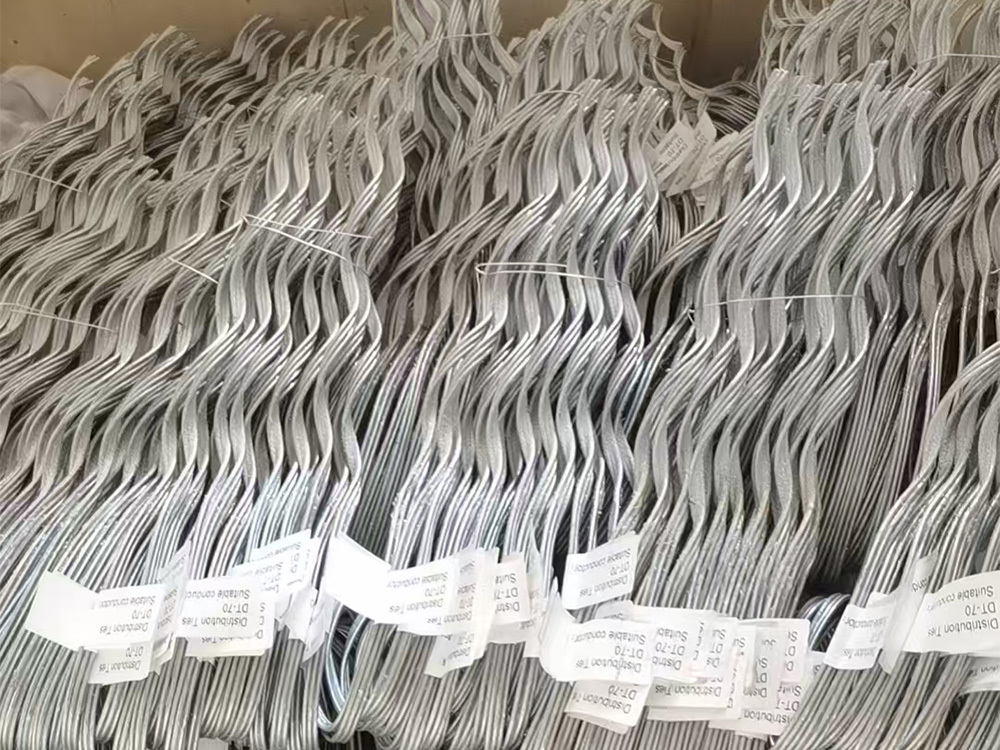

Spring & Piano Wire(Zn/Zn-Al Coated)

High-quality carbon steel (SWRH62A / 72A / 72B / 82A / 82B, SWPA / SWPB, SWRS82A/82B), Customized.

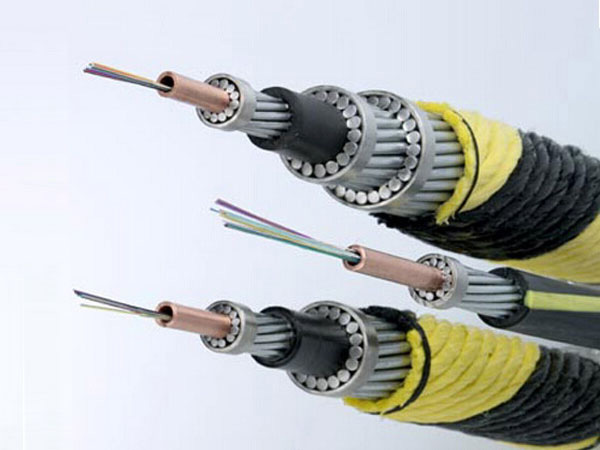

Subsea Cable Wire (Zn / Zn-Al Coated)

Strength Level:From Grade 34 (340–540 MPa) to Grade 165 (1650–1900 MPa), or per customer requirement

Application:Used in automotive seat frames (front and rear), offering excellent formability, weldability, and anti-corrosion performance