Contact Us

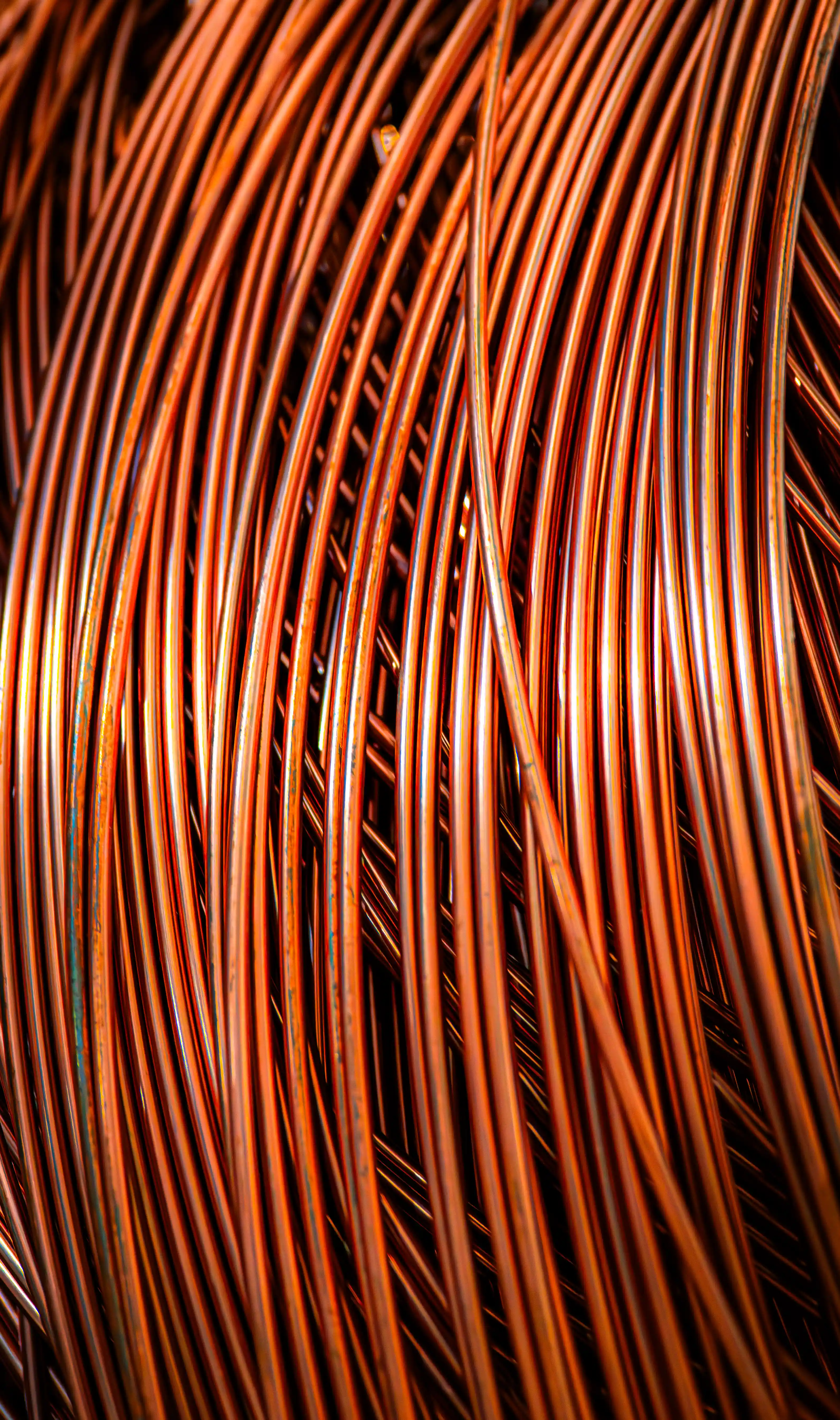

Patented Wire (Zn / Zn-Al Coated)

High-quality carbon steel: 10#/20#/45, 60#/62A/62B, 70#/72A/72B, 80#/82A/82B, 87A/87B, 92A, etc.

MOQ: 500KG

Contact

E-mail: peter@wx-hfkj.com

Classification

Technical Parameter

| Attribute | Details |

| Model No. | Customized |

| Cross-Section Shape | Round |

| Diameter | 1.0 – 12.0 mm |

| Tensile Strength | 900 / 1000 / 1100 / 1200 / 1300 MPa |

| Surface Condition | Zinc or Zinc-Aluminum alloy coated; optionally phosphated or bright finish |

| Standards | Enterprise standard or per customer specification |

| Coiling Method | Coiled type, spider type, wheel type, Z2/Z3 spool-free |

| Application | ·For redrawing after lead bath quenching and hot-dip Zn/Zn-Al coating; ·Used for production of ultra-high strength, thick-coated rope wire, spring steel wire, subsea cable wire, tubing wire, and other high-grade wires |

| Brand | OEM / Custom |

| Form | Coil wire / Straightened wire / Custom packaging |

Keywords:

Patented Steel Wire

Zinc/Zn-Al alloy coating

Related Products

Spring Wire / Piano Wire(Uncoated)

SWRH62A / SWRH72A/72B / SWRH82A/82B / SWPA / SWPB / SWRS82A/82B (high-grade carbon steel)

Spring & Piano Wire(Zn/Zn-Al Coated)

High-quality carbon steel (SWRH62A / 72A / 72B / 82A / 82B, SWPA / SWPB, SWRS82A/82B), Customized.

Application:Used in automotive seat frames (front and rear), offering excellent formability, weldability, and anti-corrosion performance

ACSR Core Wire (Zn / Zn-Al Coated)

High-quality carbon steel (produced per customer-specified strength requirements)