Contact Us

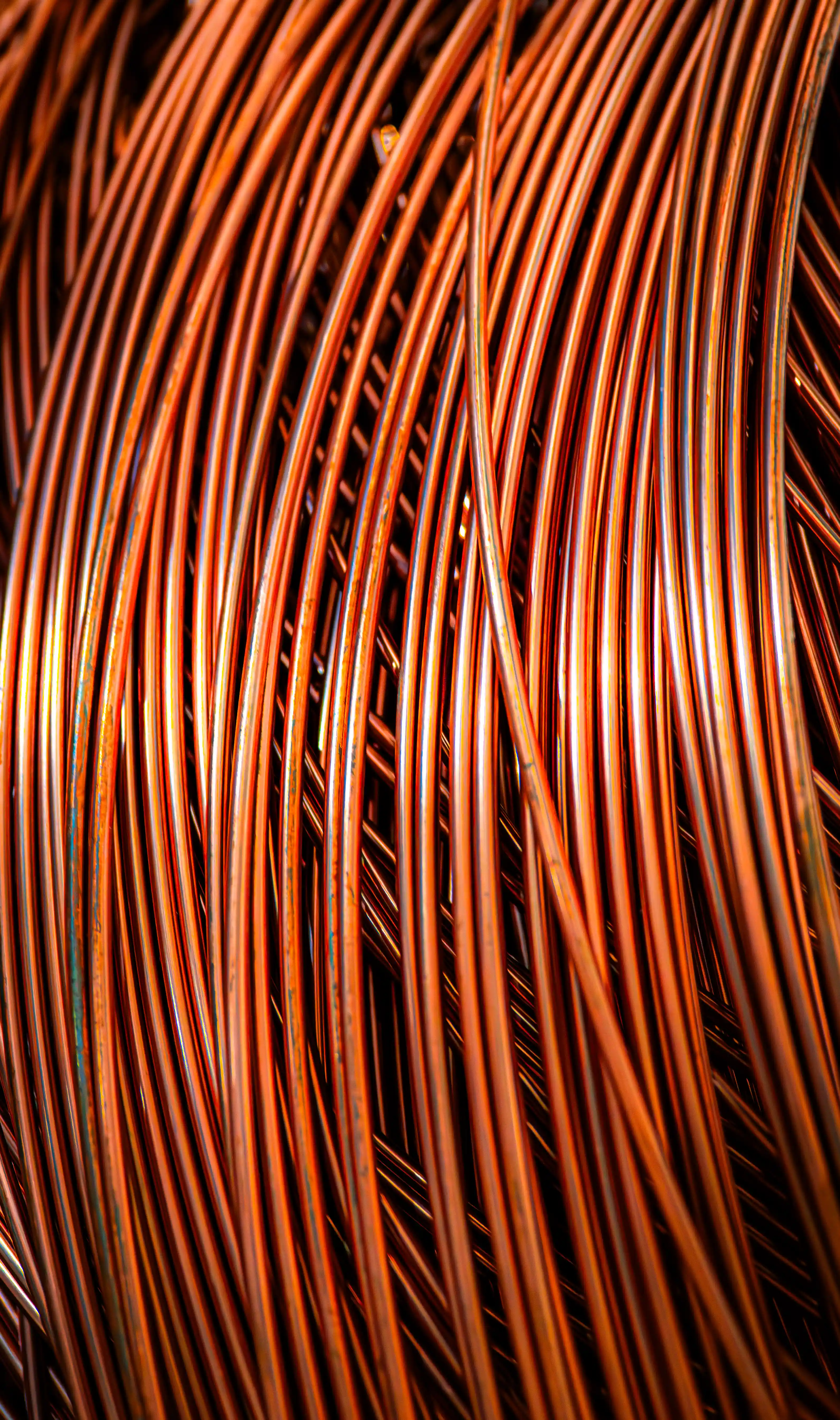

Low Carbon Steel Wire(Uncoated)

Application:Widely used in automotive seat frames (front and rear), offering excellent formability and weldability

MOQ: 500KG

Contact

E-mail: peter@wx-hfkj.com

Classification

Technical Parameter

| Attribute | Details |

| Wire Diameter | 1.8 – 12.0 mm |

| Material | 10, 15, 20; S10C, S20C; C9D, C10D, C20D; 1008, 1017, 1018; SWRCH10A, SWRCH18A, SWRCH22A; Q195, Q235; SWRM10 |

| Strength Grade | SWM-B, 550 MPa, 600 MPa, 650 MPa, 800 MPa, etc. |

| Surface Condition | ①Phosphated ② Zinc or Zinc-Aluminum alloy coated ③ Copper plated |

| Surface Quality | Free from cracks, laps, rust, oxide skin, scratches, or other visible defects (checked by eye or low magnification) |

| Standards | JIS G 3532, GB 3206-82, YB/T 5303-2010, etc. |

| Coiling Method | Coil type, spider type, Z2/Z3 spool-free, wheel type, etc. |

| Brand | OEM / Custom |

| Form | Coil wire / Straightened wire / Custom packaging |

Keywords:

Low Carbon Steel wire

Related Products

Spring Wire / Piano Wire(Uncoated)

SWRH62A / SWRH72A/72B / SWRH82A/82B / SWPA / SWPB / SWRS82A/82B (high-grade carbon steel)

Spring & Piano Wire(Zn/Zn-Al Coated)

High-quality carbon steel (SWRH62A / 72A / 72B / 82A / 82B, SWPA / SWPB, SWRS82A/82B), Customized.

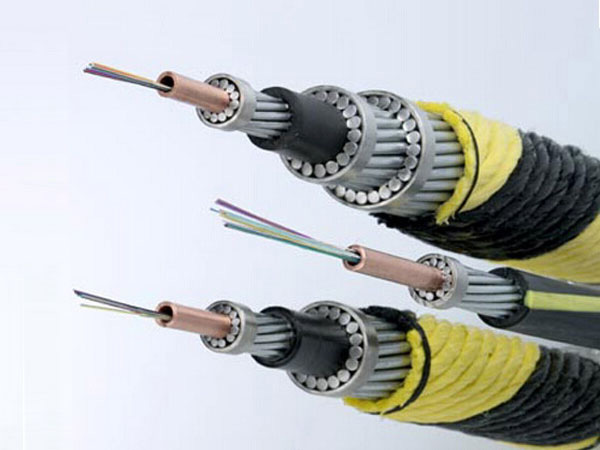

Subsea Cable Wire (Zn / Zn-Al Coated)

Strength Level:From Grade 34 (340–540 MPa) to Grade 165 (1650–1900 MPa), or per customer requirement

Application:Used in automotive seat frames (front and rear), offering excellent formability, weldability, and anti-corrosion performance