Contact Us

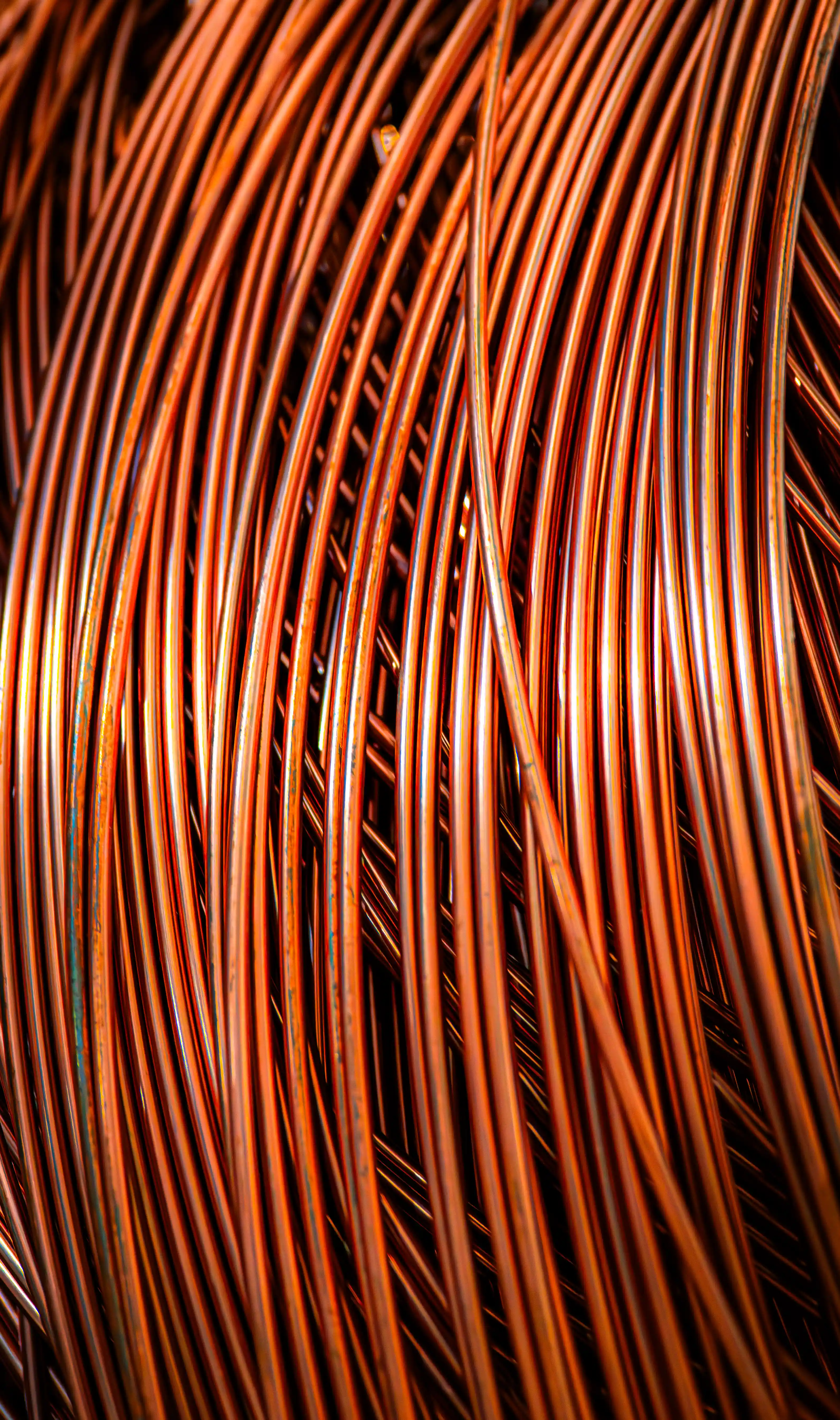

Plastic-Coated Wire

Steel Core Material:65Mn, 72A/72B, 82A/82B, or customer-specified materials

MOQ: 500KG

Contact

E-mail: peter@wx-hfkj.com

Classification

Technical Parameter

| Attribute | Details |

| Application | Used primarily in automotive seat systems, especially lumbar support assemblies |

| Wire Diameter | 1.5 – 4.5 mm |

| Coating Material | Plastic coating: PP, PE, etc. |

| Typical Specifications | 2.35×3.35 mm, 2.5×3.5 mm, 3.4×4.4 mm (outer coated dimensions) |

| Surface Color Options | Black, yellow, orange, blue, or other customer-specified custom colors |

| Cladding Thickness | As specified by OEM or host factory |

| Mechanical Properties | In accordance with national spring steel wire standards or host factory technical specs |

| Coiling Method | Z4 (cut-to-length) – see “Z4 Packing Method” for dimensional details |

| Brand | OEM / Custom |

| Form | Straightened & cut-to-length wire / Custom packaging |

Keywords:

Plastic Coated

Automotive Seats

Related Products

Spring Wire / Piano Wire(Uncoated)

SWRH62A / SWRH72A/72B / SWRH82A/82B / SWPA / SWPB / SWRS82A/82B (high-grade carbon steel)

Spring & Piano Wire(Zn/Zn-Al Coated)

High-quality carbon steel (SWRH62A / 72A / 72B / 82A / 82B, SWPA / SWPB, SWRS82A/82B), Customized.

Application:Used in automotive seat frames (front and rear), offering excellent formability, weldability, and anti-corrosion performance

ACSR Core Wire (Zn / Zn-Al Coated)

High-quality carbon steel (produced per customer-specified strength requirements)